| Bilstein Shock Install How to

One set of the shocks comes with new nuts and the others dont - You also need rear insulator nuts # F65Z-18197-BB

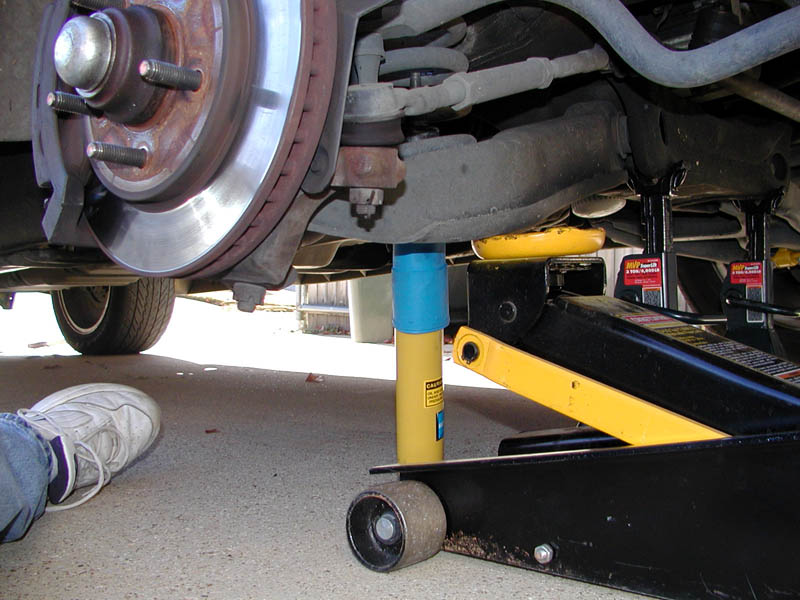

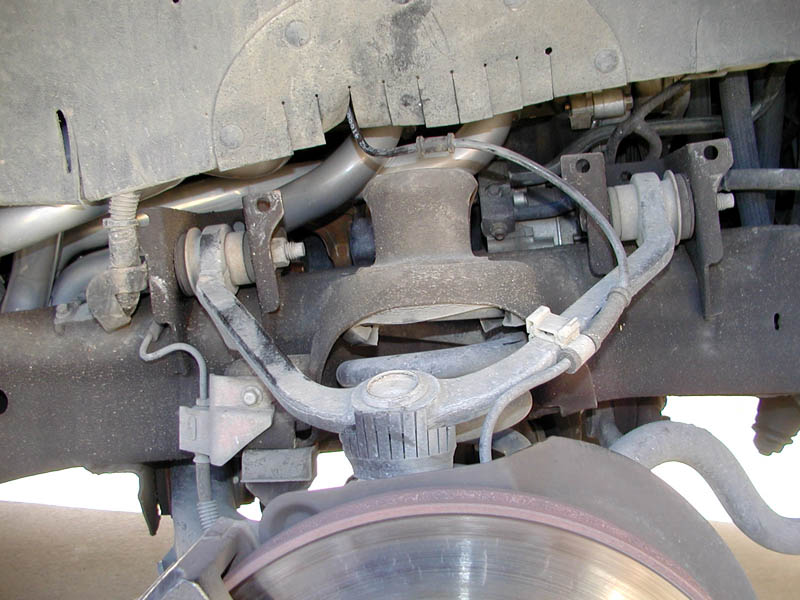

Carefully jack up the front end and support

the truck on jack stands that are rated to hold the weight of the truck.

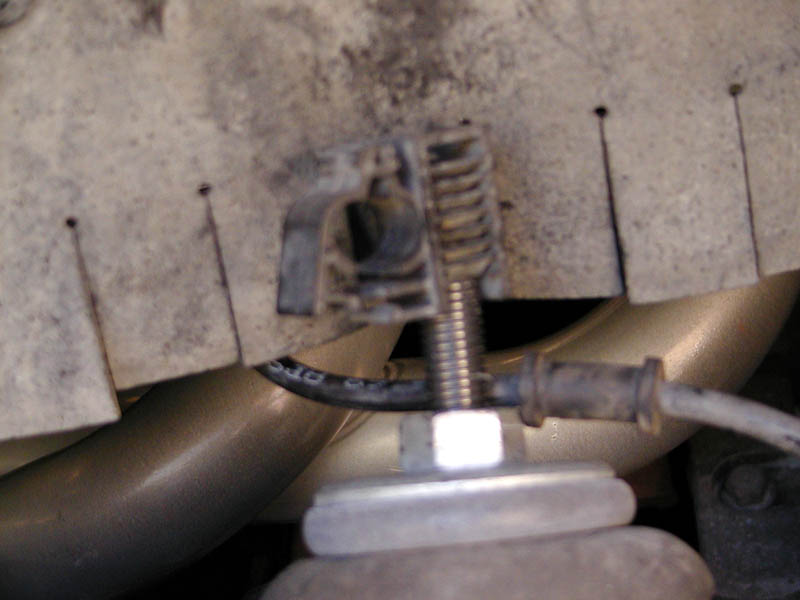

Use a flat bladed screwdriver to remove line from this clip. then the clip unscrews off

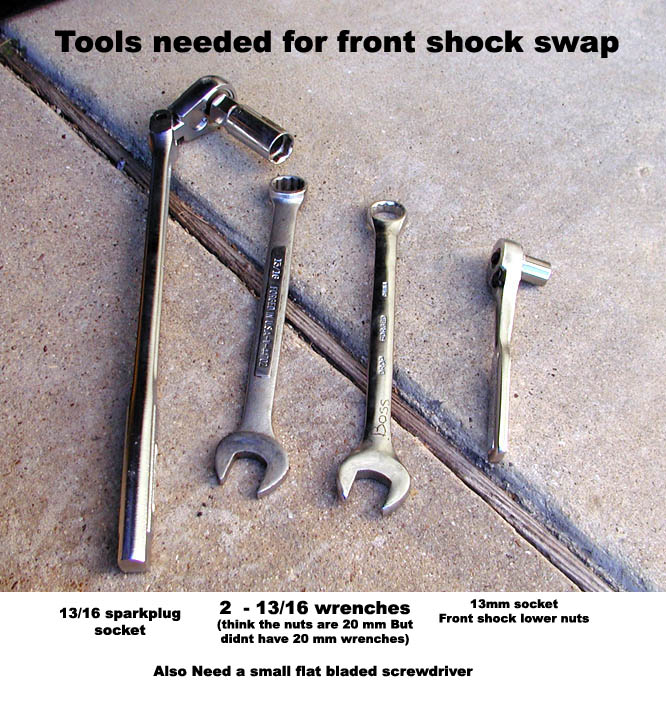

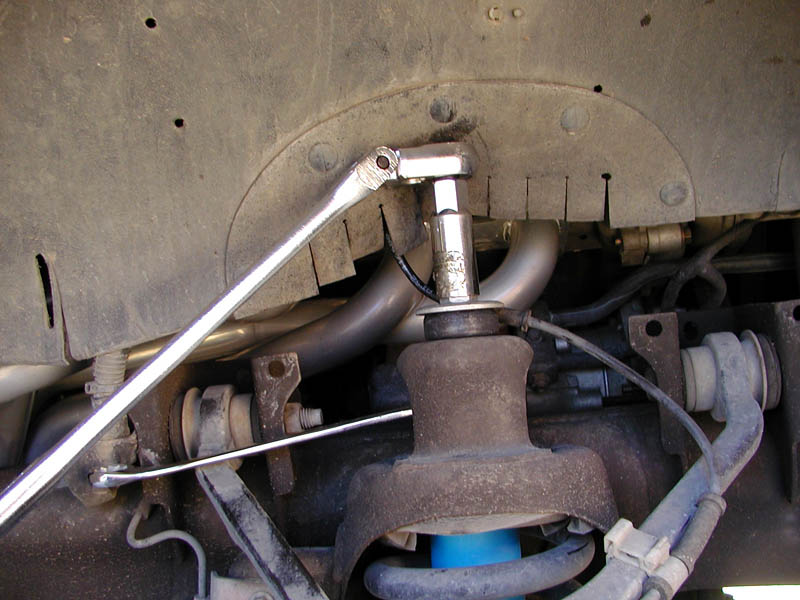

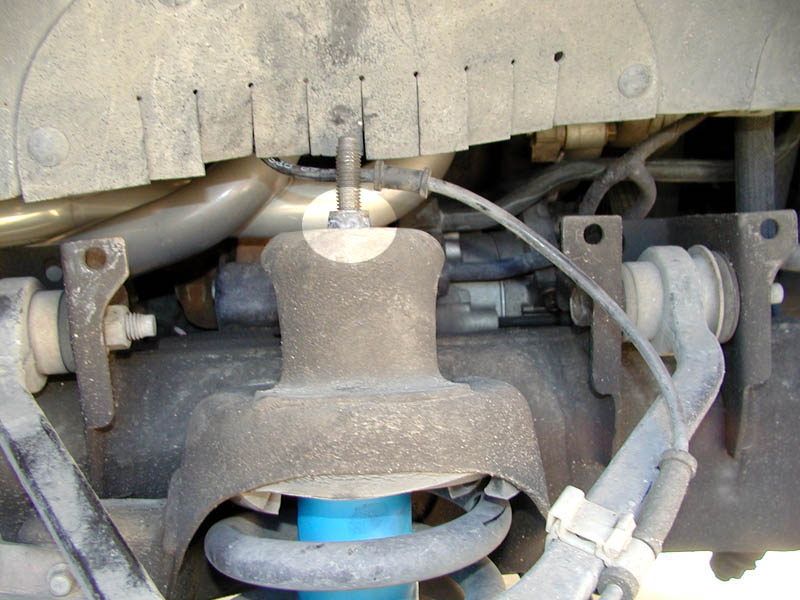

13/16 sparkplug socket works well on the

pass side to get the top nut off Drivers side has a frame member that make

the top nut removal a little tougher,

Remove the 2 13mm bottom nuts and the shock comes out the bottom.

The new one goes back in the same way.

The 13mm nuts are to be tightened to 22-29 ftlbs

Once you get shock slid into place and

lower nuts on -

You want to be sure that the rubber

cone is up through the top of the tower before you install and tighten the

upper nut

Finally tighten the upper nut until

the shock is fully seated The book says 35-46 ft lbs The rear shocks are pretty straight forward - The drivers side top has a frame rail in the way and the shocks are compressed by a band. What I did was install the bottom of the shock and then cut the band and point the top into the hole - If you are good you can thread the needle as the shock expands... After 50,000 miles on the stock 2000

shocks the Bilisteins were a VAST improvement.

SVTLightnings.com recommends you

have professional help when servicing your vehicle.

|